This guide is to help you in building your own four-legged walker as described

Description

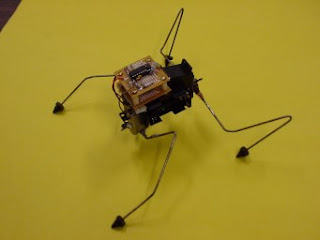

The walker was build with the following in mind: easy to build, reliable, robust, not too expensive, battery operated and using common parts. It will be a basic walker without any sensors or a reverse mechanism. You can add these as you like. The walker uses the a MicroCore invented by Mark W. Tilden,a Pulse Naturalising Circuit PNC to start-up and two H-bridges. A power regulator is added to make it possible to use a wider range of power supplies. And a Zoelen bridge is used to drive the two H-bridges. This will prevent energy losses at start-up and prevent too much load on the MicroCore.

Specifications

Height : 115 mm

Width : 160 mm

Length : 180 mm

Weigth excl. battery : 142 Gram

Frontleg swing angle : 90 Degrees

Rearleg swing angle : 90 Degrees

Speed : 18 sec/metre

[ 0.056 m/s ]

Power supply : 3-15 V

Power comsumption : 100 mA

Motor and motor driver

First you need to find your motors. I used two servo's because they include a gearbox and a nice casing to hold the rest of your walker. These servos will eventually determine the size and shape of your walker. Other DC motors can be used. You need a DC motor that has enough torque and an output of about 25 RPM. The less Amps the motor uses the better. I will assume that you will use a DC motor within the range off 1.5V - 5V and < 200mA. If the DC motor uses more current or a higher voltage then you have to consider to connect the H-bridges to a separated power supply and/or using higher rated transistors.

You have to prepare a servo for use as a regular DC motor with gearbox. To do this you need to open the casing and get the PCB and potentiometer out of it. To remove them you sometimes need to desolder the PCB, potentiometer or both. Only leave the DC motor in the casing. You don't have to remove the end-stop, because this will later prevent the legs from turning too much. However you will have more flexibility if you remove them. Now you will have a nice gearbox with a DC motor and a lot of empty space in the casing. This space can be filled with a motor driver. Since a cheap DC motor uses 100mA or more to operate its better to drive them with a H-bridge. A H-bridge is easy to build and can be used for many types of DC motors.

Parts list

Transistors : 4x PNP [2N2907], 2x NPN [2N2222]

Capacitor : 1x 22nF

Resistors : 2x 47K

These components can be placed in the now empty casing. Lead the four wires out of the casing. One for +VCC, one for -GND and two for the turning direction. Before you close the casing you need to check if the H-bridge works. Apply a battery to the right wires and hold one of the other wires at the +VCC. The servo should turn now. And if you hold the other wire at +VCC then the servo has to turn in the opposite direction. Now close the casing again and prepare the other servo.

Frame

The width of your servos will define the minimum width of your walker body. Now you need to reserve some space between the front and rear servo to place the MicroCore, a start-up circuit, voltage regulator and the driver for the H-bridge. I use this driver because i want to disable the servo's when i start-up the MicroCore. You can draw your own PCB or use the one i have used. However this PCB isn't optimised. There are a few wire bridges needed to connect all parts.

Parts list

IC's : 1x 74HC14, 1X 74HC139

Capacitors : 4x 0.22uF, 1x 2.2uF

Resistors : 3x 1M, 1x 2k7

Diodes : 1x 1N4148

Other : 2 IC sockets, 2x 5M vario-resistor, LED red, battery holder, power switch

Power regulator parts

5V - 78T05 or

3V - LD1117

Capacitors : 2x 10uF/16V

The added power supply circuit is build around a voltage regulator. Because of the low power comsumption of the walker you can use a small regulator that is able to provide about 100mA. Using this power supply is optional and not required if you use the right voltage already. Please note that the pin numbers may not be correct for other type of regulators. So always check these before installing.

In the example circuit i use a 75T05 regulator with will give an output voltage of 5V. For the actual walker i used a LD1117 3V regulator. But these are harder to find. I didn't included it on the PCB but free-wired it to the frame.

Now determine the width of you walker frame. If the width of your servo is greater then the width of the PBC then make the frame as width as the servo otherwise use the width of the PCB. Cut four pieces of PCB material as long as the width you just have determined. Now drill a few holes in them so you can connect the casing of the servo to it.

Next place the two servo's in line and the PCB in between them. Now measure the total length of it. Cut off two pieces of copper wire at this length. Solder one PCB strip at the end of the two copper wires. [see pic.] Connect the other PCB strip to the servo with a bolt/nut. Now connect the servo to the already soldered strip. Solder the other PCB strip to the copper wire. This way you know for sure that the holes in the PCB strips are aligned well. Remove the servo again. Bend the frame 30 degrees or so upwards. Repeat the same procedure for the other servo at the other end. Your frame is finished now. Adding the PCB will enhance stiffness later on.

Circuit

After creating the PCB for the circuit and drilling the holes its time to fill it with components. Start with the MicroCore. First solder the IC socket in its place. Next solder the capacitors that has to come at the solder side of the PCB. These are the three capacitors [0.22uF] that are placed on a row under the IC socket. Cut and bend the capacitor wires in the right shape before soldering. Next add the other components that are needed for a functional MicroCore

MicroCore testing

You can test the MicroCore by connecting a LED and a 2k7 resistor from one of the MicroCore outputs to GND. [pin 10 for example.] Keep in mind that the power regulator isn't installed yet. So supply the PCB with the right voltage. [3-5V] Before testing you can add the power supply if needed. If power is supplied then the LED should blink. If not then the MicroCore isn't working.

What can you do if the MicroCore isn't working?

- check the wiring

- is there a chip in the socket?

- is the chip of the right type and placed right?

- clean the solder side of the PCB with a toothbrush

- is the power connected?

- is the power turn on?

- is the LED connected right?

- did you use the right component values?

- are the vario-resistors in their middle position?

Legs

Adding legs to the walker is maybe the most crucial part of the whole design. Shape has a large impact on the walking capabilities of the walker. I made my front legs quiet longer and wider then the rear legs. This will lift the walker higher up with the same angle of turning by the servo. The rear legs are shorter and facing backwards so they can push the walker forward better. The long front legs are more flexible than the rear legs due to their length, which allows them to bend without deformation when the rear legs push the walker forward. The legs are made from copper wire and are bend in the right shape. I gave the legs a 'shoe' made of soft rubber tubing to add more friction. Now remove the wheel, cross or whatever sort of attachment that comes with the servo.

Usually these wheels or crosses has multiple holes to connect different items. Bend the leg in such form that it will cover three set of holes. Now you can fix the leg with thin metal wire for which I used a paperclip Fit the leg again to the servo. Place the walker on its back and turn the power on. Watch the leg movement and try to balance the movement by adjusting the vario-resistors. The legs should turn the same angle in either direction.

However in time the legs will still show some drift and the walker will drop on its side. I did remove the end-stop in the servo's so i had to make some new end-stop on the frame. If you didn't remove the end-stop but the legs are turning to far then you can add the following. Turn the legs in their maximum position and soldered a small piece of PCB at that place to the frame. This will stop the legs from turning to far in that direction. Repeat this on the other side and other servo. After some time using these end-stops it showed that the legs are to strong and the stops started the bend also. I had to enforce them with soldering an extra copper wire between them.

This place is for absolute begineers who are interested in electronics and robotics .Free projects,tutorials,schematics

are available here .You can paricipate here in my forum and

leave messages and comments .

HEADLINES

-

▼

2007

(29)

-

▼

October

(29)

- Guide to a 4-legged walker

- Microcore walker

- Two motor walker robot.

- c program to control speed and direction of DC motor

- Line follower robot circuit schematics

- How To Make One motor walker robot tutorial

- How To Connect Electrical Device to Parallel port

- Remote Control Jammer

- FM -JAMMER

- 5 Band Graphic Equalizer

- Rf serial port link for robot

- Simple three wheel robot with left right direction

- WALKIE /TALKIE CIRCUIT

- 2 channel RF transmitter/reciever

- How to connect motors to lpt port

- C program to control stepper motor.

- How to make eight leg walkerpod.

- H-Bridge circuit.

- PAC-MAN complete project

- Four servo motor control diagram

- 8 RELAY PARALLEL INTERFACE BOARD

- SIMPLE SERVO CONTROL DIAGRAM

- Simplified Output Interface Using parallel port

- The Simplified I/O Interface using parallel port

- WIRELESS AUDIO RECIEVER /TRANSMITTER

- RADIO CONTROL SWITCHES CIRCUIT SCHEMATICS

- CIRCUIT DIAGRAM TO CONNECT A DEVICE TO LPT PORT

- Simple C program to control computer parallel port

- PICTURES OF MY SPIDE-BOT

-

▼

October

(29)

Guide to a 4-legged walker

Microcore walker

The Microcore walker is a amazing walker. The circuit of the walker is a Microcore. The Microcore is easy to understand and easy to modify. This walker make big step.

Circuit :

1- 74HCT14

1- 74HCT245

4- 0.47uf capacitors <== This is why it make big step

4- 1 meg resistors

2- PCB boards

1- switch to power my creature

1- switch for the PNC (Process Neutralization Circuit)

Microcore circuit

Here is the Microcore circuit. If you want to modify this circuit you can change the capacitors value (.22) or the resistors (1Meg)

• All capacitors value are 0.22uf Bi-polar

• All resistors are 1 MegW

• Power from 3 Volts to 10 Volts

Put a capacitors from 10 to 20 uf across the power source.

This is for spike remover. I didn't know this trick before, my robot didn't work. I spend two day finding the problem and it was the capacitor that I didn't put.

This is only if you put motors. On my breadboard, the Microcore was working great. When I attach motors to the Microcore it didn't work, the motors didn't turn.

This is the motor drive I use in my my Microcore Walker

Chassis :

2- modify servo motors

2- AA battery holder

1- coat hanger for the leg

2- plastic horn to attach the leg to the servos

Here are some advantage and disavantage and some improvement for this robot.

Avantage :

• The circuit if very easy to understand.

• It make BIG step 9 cm or 3.5 inch.

• Compact design.

• Robust.

• Only need one IC chip for the motor drive. (with servo)

• Climb obstacles.

Disavantage :

• Always need to to press that PNC

• The PCB board take alot of space (Freeform would be good)

• Doesn't back up like is brother the two motor walker

Two motor walker robot.

The two motor walker is a walker with reverse. When it hit a obstacle with is front feeler it will back up and turn for 5 seconds.

Circuit :

1- 74HCT245

4- .22uf Bi-polar capacitors (Violet)

1- 30uf capacitor (Yellow)

2- 47K resistors (Green)

3- 1.6 Meg resistors (Red)

1- 2.5Meg resitor (Blue)

1- switch to power my creature

2- switch for the front and back feeler.

H-bridge:

4- 100K resistors

8- NPN 2N3904 Transistors

4- PNP 2N3906 Transistors

2- Servo motors

Chassis :

2- servo motors

2- AA battery holder from old electronic Kit

1- coat hanger for the leg.

2- plastic horn to attach the leg to the servos

1- metal case to hold the electronic component from a Super Nitendo Bazooka

1- switch from a Walkman for the power

2- switch for feeler from a VCR

1- mecano bar to hold the motors

Here are some advantage and disadvantage and some improvement for this robot.

Advantage :

• The circuit if very small and protect from impact.

• Compact design.

• Back up and turn when it hit a obstacle.

• No need of PCB board.

Disadvantage :

• The circuit is not easy to understand.

• Make small step

• Doesn't climb big obstacles

c program to control speed and direction of DC motor

/*

FILE: PWM.C

DESC: Control speed and direction of a DC motor using PWM

*/

#include stdio.h

#include stdlib.h

#include dos.h /* outportb, inportb defined here */

#include conio.h /* formatted text functions defined here */

void pwm(int, int, int, int);

void main(void) {

int BASEADDR;

int PORTA, PORTB, PORTC;

int CNTRL;

int DutyCycle;

int SpeedOption;

int Enable, Phase; /* Enable on A.0, Phase on A.1 */

clrscr(); /* clear screen */

window(5,5,75,30); /* set up text window */

gotoxy(1,1); cprintf("Enter Base Address (decimal) e.g. 608 =>\n");

gotoxy(42,1); scanf("%d", &BASEADDR);

PORTA = BASEADDR;

PORTB = BASEADDR + 1;

PORTC = BASEADDR + 2;

CNTRL = BASEADDR+3;

outportb(CNTRL, 128); /* configure all ports for output */

outportb(PORTA, 0); /* motor should be off */

gotoxy(1,3); cprintf("Speed Options");

gotoxy(1,4); cprintf("(f)aster");

gotoxy(1,5); cprintf("(s)lower");

gotoxy(1,6); cprintf("(r)everse direction");

gotoxy(1,7); cprintf("(q)uit");

gotoxy(1,9); cprintf("Selection => ");

gotoxy(14,9);

DutyCycle = 0; /* start off at zero velocity */

Enable = 1;

Phase = 0;

do {

while (!kbhit()) {

pwm(PORTA, DutyCycle, Enable, Phase);

}; /* end of while */

SpeedOption = getch();

switch(SpeedOption) {

case 102 : /* 102 ASCII is f */

/* increase speed by 10% DC */

DutyCycle = DutyCycle + 5;

if(DutyCycle > 100) {

DutyCycle = 100;

gotoxy(1,20); cprintf("Can't go faster");

delay(200);

gotoxy(1,20); cprintf(" ");

};

gotoxy(1,13); cprintf("Going faster...\n");

Enable = 1;

pwm(PORTA, DutyCycle, Enable, Phase);

break;

case 115 : /* 115 ASCII is s */

/* decrease speed by 10% DC */

DutyCycle = DutyCycle - 5;

if(DutyCycle < 0) {

DutyCycle = 0;

gotoxy(1,20); cprintf("Can't go slower");

delay(200);

gotoxy(1,20); cprintf(" ");

};

gotoxy(1,13); cprintf("Going slower...\n");

Enable = 1;

pwm(PORTA, DutyCycle, Enable, Phase);

break;

case 114 : /* 114 ASCII is r */

/* reverse direction at present DC */

Enable = 1;

if(Phase == 0) {

Phase = 2;

} else if(Phase ==2) {

Phase = 0;

};

pwm(PORTA, DutyCycle, Enable, Phase);

gotoxy(1,13); cprintf("Reversing.....\n");

break;

case 113 : /* 113 ASCII is q */

gotoxy(1,22); cprintf("Quitting");

outportb(PORTA, 0);

outportb(PORTB, 0);

outportb(PORTC, 0);

exit(0);

break;

}; /* end of switch */

gotoxy(14,9);

} while(1); /* end of do */

}; /* end of main */

void pwm(int PORTA, int DutyCycle, int Enable, int Phase) {

int OnTime, OffTime, TotalTime;

TotalTime = 100; /* 100 msec */

OnTime = (int)(TotalTime * DutyCycle / 100);

OffTime = (int)(TotalTime - OnTime);

outportb(PORTA, Enable+Phase);

delay(OnTime);

Enable = 0;

outportb(PORTA, Enable+Phase);

delay(OffTime);

gotoxy(1,10); cprintf("Duty Cycle is %3d", DutyCycle);

return;

}; /* end of pwm */

How To Make One motor walker robot tutorial

Parts:

1 x modify servo motor

1 x servo horn

1 x 1 cm plastic or metal tube

1 x metal rod that fit in the plastic or metal tube

1 x coat-hanger

1 x 1.5 inch gear (4 cm)

1 x Freeform Bicore

1 x AA or AAA battery holder

1 x switch on/off

1 x nail for the stop mechanism (optional)

Take the gear

cut it in half

Take the servo horn and glue it on the half gear

Take the other half gear, and glue the tube exactly in the center hole

Take the metal rod, and bent it like picture below

Glue the rod on the servo, like the picture underneath.

Put everything in place. Take the half gear with the tube and place it on the metal rod. Bend the rod so the two half gear touch each other.

Now add the terminal block to block the half gear in place.

It is time to give some leg to your creature. Take a 8 gauge wire or a coat hanger to make the leg.

Glue each leg on the half gear.

Now glue the two battery holder on each side of the servo.

Take the freeform circuit of the BICORE and glue it on the top of the servo.

Participate in my new msg forum and share projects and Tutorials

MESSAGE BOX -- subscribe below to get updates

OR MAIL ME AT .... abhishekrobotics@gmail.com

Augmented reality onboard the ISS? 14 Oct 2007 17:11, Tech blogs on ZDnet

Massachusetts high schools vying to update old science labs 14 Oct 2007 12:30, The Boston Globe Online

Robots vie in fight of racks, ringers 14 Oct 2007 10:50, Contra Costa Times

Teens build, enter machines in contest 14 Oct 2007 10:11, San Mateo County Times

New NASA software to ease astronauts' tasks in adverse space conditions 14 Oct 2007 08:11, Big News Network